01Working Principle

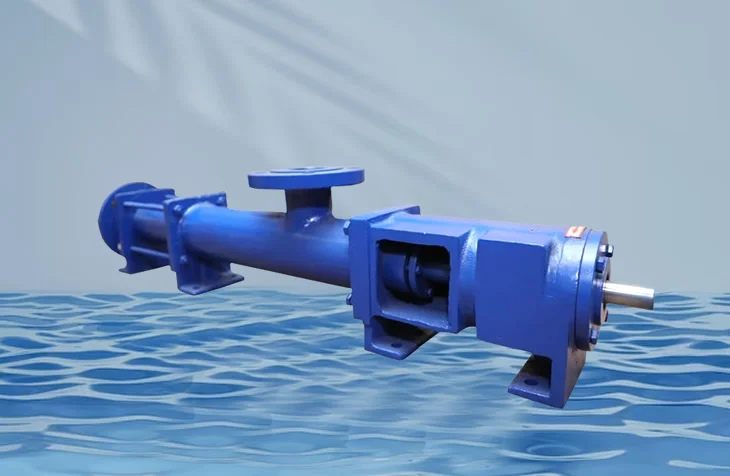

- The pumping elements are stator and rotor.

- The stator is made of resilient elastomeric materials and bonded to stator tubes.

- A single helical rotor rolls eccentrically in double threaded helix stator of twice the pitch length

- The opposing cavities fill and empty simultaneously resulting in a pulsation less flow

- The liquid travels axially with relatively low velocity and minimum agitation.

03Features

- Positive Displacement- As having a single rotating element, progressive cavities are generated and it gives a uniform and metered flow required.

- Non- Clogging- It can handle solid in suspension or media having a high percentage of solids

- Self Priming- can work in negative suction, so do not require a foot valve.

- Silent Running- As the rotor runs inside the steady stator, so it makes a little noise. Gentle pumping action minimizes shear and crushes damage.

- Reversible- As it has a reversible rotation capability; a progressive cavity pump can perform with the same efficiency in the clockwise or anti-clockwise direction.

- Low NPSH Requirement- As having a suction lift capability it can perform in vacuum condition.

- Separate Bearing Housing- Fluid cannot enter in the bearing housing which gives the life to bearings and easy for maintenance

- Low running speeds- ideal for abrasive applications.

- Stators are available in a wide range of elastomeric as per application.

- Easy to dismantle and assemble without special tools.

05Material

- BEARING HOUSING- GREY CAST IRON, SS 304, SS316, SS 316L, HASTELLOY & SPECIAL ALLOYS

- STATOR- NATURAL, NITRILE, EPDM, VITON, SILICON, FOOD GRADE RUBBER ETC

- ROTOR- HEAT TREATED EN STEEL, SS 304, SS317, SS316L, AND SPECIAL ALLOYS

- OTHER ROTATING PARTS- Cr STEEL, SS 304, SS 316, SS316L, AND SPECIAL ALLOYS

05Typical Parameters

The impeller of the Aircooled thermal oil pumps are single entry, closed type and dynamically balanced. The impeller has back Ring & Holes between each fin for the axial balancing of pressures.

| Capacity | Up to 60m3/hr |

| Pressure | Up to 24 kg/cm2 |

| Temperature | Up to 150 degrees C |

| Viscosity | Up to 120000 CST |